Are you curious about how OEM sheet metal fabrication works and why it plays such a vital role in the manufacturing world? You're in the right place! This guide dives deep into the precision, technology, quality control, customization, and collaborative strategies that define the OEM sheet metal fabrication industry.

What You’ll Discover About OEM Sheet Metal Fabrication

This guide covers the entire OEM sheet metal fabrication process, from design to delivery. It explores the technologies used, quality assurance methods, specialization, supply chain roles, partnerships, emerging trends, real-world examples, sustainability efforts, and how to choose the best OEM partner—highlighting Atlas Manufacturing as a top example.

Understanding the OEM Sheet Metal Fabrication Process

OEM sheet metal fabrication is a complex and precise operation that starts with concept development and ends with final product delivery. Every step, from material selection to cutting, forming, and finishing, must be executed with exactness. The goal is to produce parts that not only meet specifications but also integrate seamlessly into the final product, ensuring optimal performance and reliability.

Why Precision and Quality Matter in OEM Manufacturing

In OEM manufacturing, there's no room for error. Tight tolerances and high accuracy are essential to ensure components fit perfectly within larger systems. Reputable OEMs invest heavily in advanced tools and skilled personnel to maintain these standards. Their commitment to quality ensures that every part contributes to the overall success of the end product, whether it's an automotive component, industrial machine, or medical device.

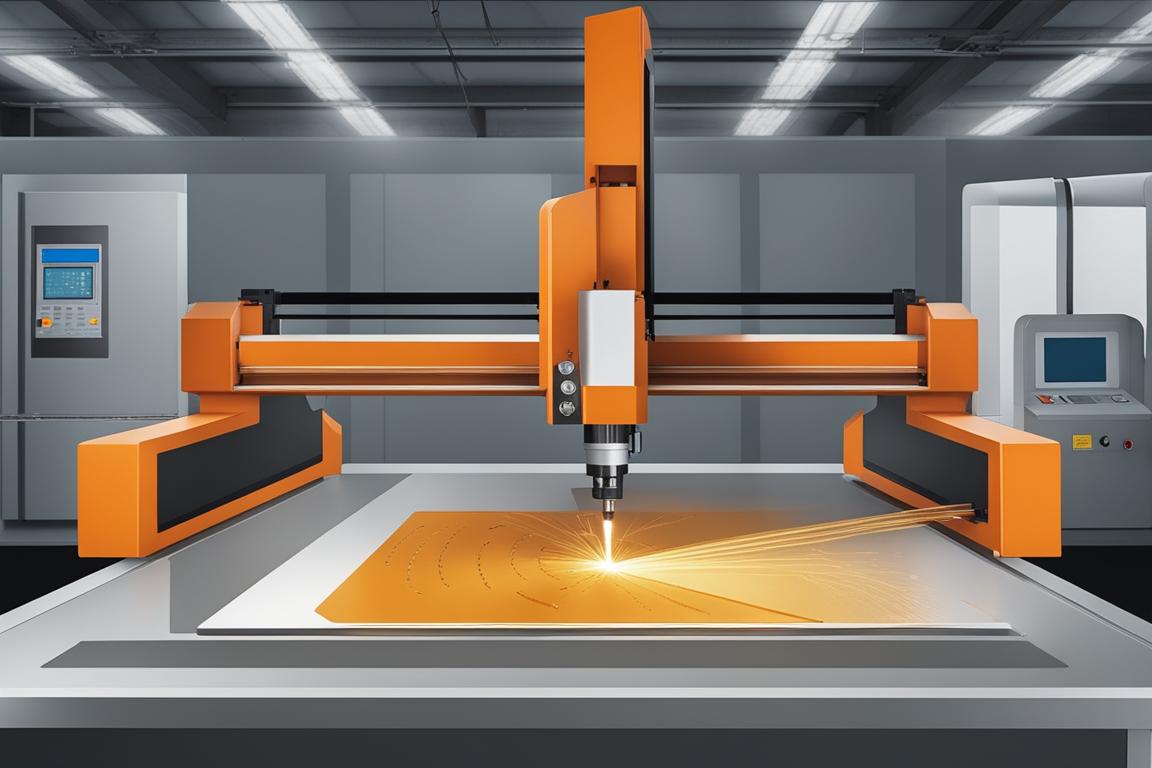

Cutting-Edge Technologies in OEM Sheet Metal Fabrication

The field of OEM sheet metal fabrication is constantly evolving thanks to new technologies and innovations. These advancements allow manufacturers to deliver higher-quality products faster and more efficiently than ever before.

Key Technologies Used by OEMs

OEMs rely on a variety of advanced machinery and techniques to achieve precision and efficiency. Some of the most commonly used include:

- Punch Presses: Ideal for accurate and fast cutting of sheet metal using various tooling options.

- Laser Cutting: Offers unmatched precision for complex shapes and designs.

- Welding: Essential for joining metal components securely and durably.

- Machining: Used to refine dimensions and ensure tight tolerances.

- Forming: Shapes metal sheets into the desired form using specialized equipment.

| Technology/Technique | Description |

|---|---|

| Punch Presses | Utilized for precise cutting of sheet metal with different tooling options. |

| Laser Cutting | Enables intricate designs and precise cutting of various metals. |

| Welding | Essential for joining metal components together. |

| Machining | Used for refining part dimensions and achieving high accuracy. |

| Forming | Involves shaping metal sheets into desired forms. |

Quality Control and Certifications in OEM Fabrication

Quality is at the heart of OEM sheet metal fabrication. To ensure consistency and reliability, many companies pursue certifications like ISO 9001:2015, which verify their adherence to strict quality management systems.

Why Quality Matters

Certifications not only validate a manufacturer’s commitment to quality but also assure clients that they’re working with a reliable partner. A strong focus on on-time delivery, scalability, and consistent performance helps OEMs build long-term relationships with their customers.

Customization and Specialization in OEM Sheet Metal Fabrication

OEMs excel in delivering tailored solutions that meet the unique needs of different industries. Whether it's agriculture, construction, or healthcare, OEMs adapt their processes to provide the best possible outcomes.

Tailored Solutions for Specific Industries

By focusing on specific sectors, OEMs can develop deep expertise and offer highly customized parts. This specialization allows them to address industry-specific challenges and deliver products that align perfectly with client requirements.

OEMs in the Manufacturing Supply Chain

OEMs play a crucial role in the broader manufacturing ecosystem. They act as key suppliers of critical components that help drive production across multiple industries.

Supporting Diverse Industries

OEMs provide essential parts that serve as building blocks for a wide range of products. Their contribution ensures that manufacturers have access to high-quality, precision-engineered components that support innovation and efficiency in production.

Collaborative Partnerships in OEM Fabrication

Successful OEM projects often depend on strong, collaborative relationships between manufacturers and fabricators. These partnerships foster innovation, shared goals, and long-term success.

Benefits of Strong OEM Relationships

Building solid partnerships with OEMs allows manufacturers to tap into specialized knowledge and resources. This collaboration leads to better products, improved efficiency, and greater customer satisfaction.

Trends and Innovations in OEM Sheet Metal Fabrication

The industry is continuously advancing, driven by new technologies and changing market demands. OEMs are leading the way in adopting these innovations to stay competitive and deliver superior results.

Embracing the Future of Fabrication

OEMs are investing in automation, digital design tools, and data-driven processes to improve efficiency and reduce waste. These changes not only enhance productivity but also allow for more flexible and responsive manufacturing solutions.

Real-World Success Stories

Case studies and real-life examples demonstrate the impact of OEM sheet metal fabrication on businesses and industries. These stories highlight how collaboration and expertise lead to successful outcomes.

Showcasing Industry Achievements

From custom parts for aerospace applications to large-scale industrial components, OEMs consistently deliver high-quality solutions that exceed expectations. These success stories underline the value of choosing the right partner for your sheet metal needs.

Sustainability and the Future of OEM Fabrication

As environmental concerns grow, OEMs are increasingly adopting sustainable practices to reduce their carbon footprint and promote eco-friendly manufacturing.

Eco-Friendly Manufacturing Practices

OEMs are now using recycled materials, energy-efficient machines, and waste-reducing techniques to support green initiatives. This shift not only benefits the environment but also enhances brand reputation and long-term viability.

How to Choose the Right OEM Partner

Selecting the right OEM partner is crucial for ensuring the quality, reliability, and cost-effectiveness of your sheet metal fabrication needs.

Key Factors to Consider

When choosing an OEM, look for experience, technical capabilities, and a proven track record. A good partner will understand your needs, offer expert guidance, and maintain high standards of quality and service throughout the project lifecycle.

Conclusion

OEM sheet metal fabrication is more than just a manufacturing process—it's a strategic partnership that drives innovation and supports global industries. As technology advances and sustainability becomes more important, OEMs continue to evolve, offering smarter, more efficient, and more responsible solutions.

Frequently Asked Questions (FAQ)

What is OEM sheet metal fabrication?

OEM sheet metal fabrication involves producing custom metal parts specifically designed for original equipment manufacturers. These parts are built to exact specifications and integrated into larger systems or products.

Who can benefit from precision sheet metal fabrication?

Industries such as automotive, aerospace, electronics, and telecommunications benefit greatly from precision sheet metal fabrication due to the need for high-quality, custom components.

How is precision sheet metal fabrication different from regular fabrication?

Unlike standard fabrication, precision sheet metal fabrication requires extremely tight tolerances and high accuracy to meet the specific needs of OEMs, ensuring seamless integration into the final product.

What makes OEM sheet metal fabrication cost-effective?

OEMs often have the expertise, equipment, and scale to offer cost-effective solutions. By outsourcing, businesses can save time, reduce overhead, and benefit from specialized knowledge.

How can I ensure the quality of my OEM sheet metal parts?

Choose an OEM with ISO certifications, a proven track record, and robust quality control processes. These factors ensure that your parts meet the highest standards of performance and reliability.

What if I need custom designs for my OEM sheet metal parts?

A reputable OEM can work closely with you to create custom designs tailored to your specific requirements, ensuring that the final product meets your expectations and operational needs.

{"@context":"https://schema.org","@type":"FAQPage","mainEntity":[{"@type": "Question", "name": "What is OEM sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "OEM sheet metal fabrication involves producing custom metal parts for original equipment manufacturers."}}, {"@type": "Question", "name": "Who can benefit from precision sheet metal fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Industries such as automotive, aerospace, electronics, and telecommunications can benefit from precision sheet metal fabrication."}}, {"@type": "Question", "name": "How is precision sheet metal fabrication different from regular fabrication?", "acceptedAnswer": {"@type": "Answer", "text": "Precision sheet metal fabrication involves tight tolerances and high accuracy to meet specific OEM requirements."}}, {"@type": "Question", "name": "What makes OEM sheet metal fabrication cost-effective?", "acceptedAnswer": {"@type": "Answer", "text": "By outsourcing to a specialized OEM sheet metal fabrication company, you can benefit from economies of scale and expertise."}}, {"@type": "Question", "name": "How can I ensure the quality of my OEM sheet metal parts?", "acceptedAnswer": {"@type": "Answer", "text": "Look for a fabricator with ISO certifications, a proven track record, and quality control processes in place."}}, {"@type": "Question", "name": "What if I need custom designs for my OEM sheet metal parts?", "acceptedAnswer": {"@type": "Answer", "text": "A reputable OEM sheet metal fabrication company can work with you to create custom designs that meet your specific needs."}}]}Abs Thermoforming Machine,Thermoforming Vacuum Forming,Abs Plastic Case,Thermoforming Enclosure

skyshields(suzhou)thermoforming tech.co.ltd , https://www.skyshields.com