Table of Contents

- What is Sheet Metal Gauge Chart

- Aluminum Gauge Chart

- Popular Sheet Metal Materials

- Sheet Metal Applications

- Mild Steel Gauge Chart

- Galvanized Steel Gauge Chart

- Stainless Steel Gauge Chart

- Copper Gauge Chart

- Sheet Metal Fabrication

- Steel Sheet Metal Tolerances

- Stainless Steel Sheet Metal Gauge Chart Thickness

- Sheet Metal Surface Finishes

- Brass Gauge Chart

- Sheet Metal Weldings

- Stainless Steel Sheet Weight

- How are Sheet Metal Gauges Used?

- Sheet Metal Advantages and Disadvantages

What is Sheet Metal Gauge Chart

A sheet metal gauge chart is a reference tool that specifies the thickness-to-weight ratio of sheet metal. It helps manufacturers understand how the thickness of the metal affects its weight and performance. Higher gauge numbers correspond to thinner sheets, while lower numbers denote thicker ones. This is particularly useful when designing components that require specific mechanical properties without wasting material.

Understanding Aluminum Gauge Chart

Knowing the exact thickness of aluminum sheets is crucial for determining their suitability for different applications. For instance, certain parts may demand robust materials with higher strength, whereas others might only need lightweight options. Proper selection ensures optimal functionality and cost efficiency. Using an aluminum gauge chart allows you to match the correct thickness to your project needs.

While selecting appropriate gauges prevents over-engineering, it also avoids under-specifying critical areas. Too heavy or thick aluminum can drive up both production and transportation expenses unnecessarily. Therefore, understanding the nuances of aluminum gauges empowers users to strike the right balance between performance and economy.

Looking for high-quality sheets in various sizes? Explore our comprehensive sheet metal gauge charts provided in millimeters and inches below!

Aluminum Gauge Chart

| Gauge No. | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|---|

| MM | 3.665 | 3.264 | 2.906 | 2.588 | 2.305 | 2.053 | 1.628 | 1.291 |

| Inches | 0.1443 | 0.1285 | 0.1144 | 0.1019 | 0.09074 | 0.08081 | 0.06408 | 0.05082 |

| Gauge No. | 18 | 20 | 22 | 24 | 26 | 28 | 30 | – |

| MM | 1.024 | 0.812 | 0.644 | 0.511 | 0.405 | 0.321 | 0.255 | – |

| Inches | 0.0403 | 0.03196 | 0.02535 | 0.0201 | 0.01594 | 0.01264 | 0.01003 | – |

Popular Sheet Metal Materials

| Stainless steel | Pre-plated steel | Cold rolled steel | Copper/Brass | Aluminum | |

|---|---|---|---|---|---|

| 400 series | 300 series | Hot-dip galvanized steel | Smoothed hot rolled steel | Electrolytically tough pitch (ETP) | Grade 1100: Low strength |

| Grade 410: Less corrosion resistant, heat treatable | Grade 316: Corrosion resistant, retains strength at high temps | Â | Available in 1018, 1008 alloys | C110 or C101 | Weldable and ductile |

| Grade 430: Used where corrosion resistance isn't necessary | Grade 304: Widely used, less corrosion resistant | Â | Â | Cartridge brass (alternative) | Grade 3003: Stronger, corrosion resistant |

| Â | Good formability and weldability | Â | Â | Â | Â |

Sheet Metal Applications

- Architectural

- Structural components

- Housings

- Enclosures

- Manufacturing

- Cabinets

- Construction

- Automation

Actual thickness and gauge value vary based on material

The gauge value serves as an independent measure that controls the sheet thickness in terms of inches or millimeters. A higher gauge number indicates a thinner sheet. Compared to ferrous metals, non-ferrous metals have distinct gauges measured in ounces per square foot.

Below are standard gauges for sheet metal charts across different materials.

Mild Steel Gauge Chart

| Gauge no. | 7 | 8 | 9 | 10 | 11 | 12 | 14 |

|---|---|---|---|---|---|---|---|

| MM | 4.554 | 4.175 | 3.797 | 3.416 | 3.038 | 2.656 | 1.897 |

| Inches | 0.1793 | 0.1644 | 0.1495 | 0.1345 | 0.1196 | 0.1046 | 0.0747 |

| Gauge no. | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| MM | 1.518 | 1.214 | 0.911 | 0.759 | 0.607 | 0.454 | 0.378 |

| Inches | 0.0598 | 0.0478 | 0.0359 | 0.0299 | 0.0239 | 0.0179 | 0.0149 |

Galvanized Steel Gauge Chart

| Gauge no. | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|

| MM | 4.269 | 3.891 | 3.51 | 3.1318 | 2.753 | 1.9939 | 1.6129 |

| Inches | 0.1681 | 0.1532 | 0.1382 | 0.1233 | 0.1084 | 0.0785 | 0.0635 |

| Gauge no. | 18 | 20 | 22 | 24 | 26 | 28 | 30 |

| MM | 1.31 | 1.005 | 0.853 | 0.701 | 0.551 | 0.474 | 0.398 |

| Inches | 0.0516 | 0.0396 | 0.0336 | 0.0276 | 0.0217 | 0.0187 | 0.0157 |

Stainless Steel Gauge Chart

| Gauge No | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|

| MM | 4.365 | 3.968 | 3.571 | 3.175 | 2.778 | 1.984 | 1.587 |

| Inches | 0.17187 | 0.15625 | 0.14062 | 0.125 | 0.10937 | 0.07812 | 0.0625 |

| Gauge No | 18 | 20 | 22 | 24 | 26 | 28 | 30 |

| MM | 1.27 | 0.9525 | 0.7937 | 0.635 | 0.476 | 0.396 | 0.3175 |

| Inches | 0.05 | 0.0375 | 0.03125 | 0.025 | 0.01875 | 0.01562 | 0.0125 |

Copper Gauge Chart

| Gauge No. | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|---|

| MM | 4.572 | 4.191 | 3.759 | 3.404 | 3.048 | 2.769 | 2.108 | 1.651 |

| Inches | 0.18 | 0.165 | 0.148 | 0.134 | 0.12 | 0.109 | 0.083 | 0.065 |

| Gauge No. | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| MM | 1.245 | 0.889 | 0.711 | 0.559 | 0.457 | 0.356 | 0.305 | |

| Inches | 0.049 | 0.035 | 0.028 | 0.022 | 0.018 | 0.014 | 0.012 |

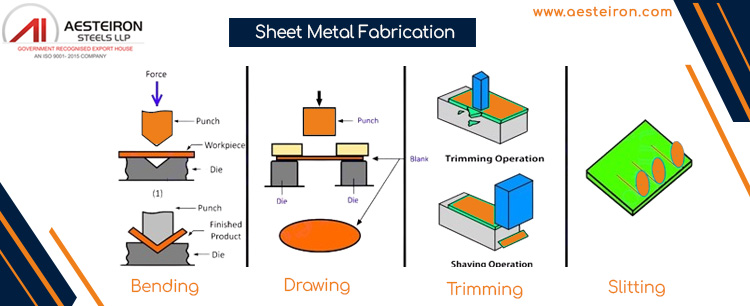

Sheet Metal Fabrication

| Bending | Cutting | Punching | Forming |

|---|---|---|---|

Creates bend lines and applies force to achieve desired angles |

Choice depends on thickness, material type, and required precision |

Done by punching press or CNC machine |

Shapes the metal into desired forms

|

| Welding | Finishing | Inspection | Â |

Ensures parts are securely attached |

Protects against corrosion |

|

|

Sheet metal gauge chart ranges from 0/7 SWG to 50 SWG

Steel Sheet Metal Tolerances

| Gauge | 10 | 11 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal [in] | 0.1345 | 0.1196 | 0.1046 | 0.0747 | 0.0598 | 0.0478 | 0.0359 | 0.0299 | 0.0239 | 0.0179 | 0.0149 | |

| Max | Size [in] | 0.1405 | 0.1256 | 0.1106 | 0.0797 | 0.0648 | 0.0518 | 0.0389 | 0.0329 | 0.0269 | 0.0199 | 0.0169 |

| Min | Size [in] | 0.1285 | 0.1136 | 0.0986 | 0.0697 | 0.0548 | 0.0438 | 0.0329 | 0.0269 | 0.0209 | 0.0159 | 0.0129 |

Stainless Steel Sheet Metal Gauge Chart Thickness

| Gauge | 12 | 11 | 24 | 16 |

|---|---|---|---|---|

| Thickness | 0.109" | 2.78mm | 0.120" | 3.05 mm | 0.025" | 0.64 mm | 0.063" | 1.59mm |

| Thickness Tolerance | ± 0.009 | ± 0.23mm | ± 0.005 | ± 0.003 | ± 0.08mm | ± 0.006 | ± 0.15mm |

| Gauge | 14 | 20 | 18 | 22 |

| Thickness | 0.078" | 1.98mm | 0.038" | 0.95mm | 0.050" | 1.27mm | 0.031" | 0.79 mm |

| Thickness Tolerance | ± 0.007 | ± 0.18mm | ± 0.004 | ± 0.10mm | ± 0.005 | ± 0.13mm | ± 0.004 | ± 0.10mm |

Sheet Metal Surface Finishes

- Annealing

- Galvanized

- Tinning

- Anodizing

- Tempering

Refer to Brass Gauge Thickness in Millimeters

The following brass gauge thicknesses are essential for customers for several reasons:

The thickness of brass influences the efficiency of the manufacturing process. For example, excessively thick brass can be difficult to cut or shape into forms. Conversely, very thin brass may bend easily and fail under stress.

It determines the structural strength and longevity of the final product.

It impacts the cost of the project. Not all parts require high thickness, and excessive thickness can increase production and shipping costs.

Thin-gauge brass can be damaged by high heat exposure. Thus, welders minimize heat exposure during welding.

Brass Gauge Chart

| Gauge No. | 7 | 8 | 9 | 10 | 11 | 12 | 14 | 16 |

|---|---|---|---|---|---|---|---|---|

| MM | 3.665 | 3.264 | 2.906 | 2.588 | 2.305 | 2.053 | 1.628 | 1.291 |

| Inches | 0.1443 | 0.1285 | 0.1144 | 0.1019 | 0.09074 | 0.08081 | 0.06408 | 0.05082 |

| Gauge No. | 18 | 20 | 22 | 24 | 26 | 28 | 30 | |

| MM | 1.024 | 0.812 | 0.644 | 0.511 | 0.405 | 0.321 | 0.255 | |

| Inches | 0.0403 | 0.03196 | 0.02535 | 0.0201 | 0.01594 | 0.01264 | 0.01003 |

Sheet Metal Weldings

MIG Welding

TIG Welding

Laser Welding

Stick Welding

Gas Welding

Plasma Arc Welding

Gauge sizes depend on the weight of steel, which is 41.82 pounds per square foot per inch of thickness.

This standard gauge for metal sheets is vital because it ensures uniformity in thickness. It directly affects the toughness, durability, and performance of the final product in manufacturing processes, which rely on precise designs and manufacturing techniques tailored to the required toughness and weight. It also provides a cost-effective solution by avoiding unnecessary excess material.

Stainless Steel Sheet Weight

| Weight Per Stainless Steel Sheet | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight KG/M2 | 1.44 | 1.6 | 1.76 | 1.92 | 2.16 | 2.24 | 2.56 | 3.04 | 3.52 | 4 | 4.48 | 5.04 | 6 | 7.04 | 8 | 9.04 | 10 | 72 | 12 | |

| Thickness (mm) | 0.18 | 0.2 | 0.22 | 0.24 | 0.27 | 0.28 | 0.32 | 0.38 | 0.44 | 0.5 | 0.56 | 0.63 | 0.75 | 0.88 | 1 | .1.13 | 1.25 | 1.38 | 1.5 | |

| Size(mm) | 2500 X 1250 | – | – | – | – | – | – | – | – | 11 | 12.5 | 14 | 15.75 | 18.75 | 22 | 25 | 28.25 | 31.25 | 34.5 | 37.5 |

| 2000 X 1000 | 2.88 | 3.2 | 3.52 | 3.84 | 4.32 | 4.48 | 5.12 | 6.08 | 7.04 | 8 | 8.96 | 10.08 | 12 | 14.08 | 16 | 18.08 | 20 | 22.03 | 24 | |

| 3000 X 1500 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 36 | 40 | 45 | 50 | 54 | |

| Weight KG/M2 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 64 | |

| Thickness (mm) | 1.75 | 2 | 2.25 | 2.5 | 2.75 | 3 | 3.25 | 3.5 | 3.75 | 4 | 4.25 | 4.5 | 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | |

| Size(mm) | 2500 X 1250 | 43.75 | 50 | 56.25 | 62.5 | 68.75 | 75 | 81.25 | 87.5 | 93.75 | 100 | 106.25 | 112.5 | 125 | 137.5 | 150 | 162.5 | 175 | 187.5 | 200 |

| 2000 X 1000 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | 64 | 68 | 72 | 80 | 88 | 96 | |||||