Remote Hull Inspection Saves $1 Million With The Elios 3

C-Bird used the Elios 3 for a hull inspection of a cargo ship—and got results more safely, quickly, and efficiently than ever before.

Key Benefits at a Glance

SAFETY—By deploying the Elios 3 for the hull inspection, we eliminated the need for scaffolding in the cargo tanks, avoiding approximately 10,000 hours of working at height in confined spaces.

COST REDUCTION—Using the Elios 3 instead of scaffolding for accessing hard-to-reach areas resulted in a direct cash saving of about $1 million during the vessel survey. This approach also significantly reduced time and logistical expenses.

ENVIRONMENTAL IMPACT—Utilizing a drone for inspections instead of rafts prevented the creation of vast quantities of oil-contaminated water that would otherwise require treatment before disposal.

IMPROVED DATA QUALITY—The onboard LiDAR on the Elios 3 allowed for precise data localization and easy sharing of findings with all stakeholders involved in the survey.

Over 90% of the world's cargo-carrying vessels are governed by the International Association of Classification Societies (IACS) Common Structural Rules (CSR).

The CSR establishes standards for designing, constructing, and operating vessels throughout their lifecycle, with specific criteria depending on the vessel classification.

Once a vessel enters service, it must renew its Class certification every five years. A major component of a vessel's Class renewal involves the Hull Survey, which assesses the structural integrity of the ship.

Crude oil tankers have some of the most demanding Hull inspection requirements because much of the structure requiring close-up examination is located inside the Cargo Oil Tanks (COT), with many critical areas unreachable by surveyors. This makes inspections particularly challenging. To access these unreachable areas within the COT, vessel owners typically either construct scaffolding or fill the tanks with water for a process called rafting.

The scale of a cargo tank is immense—scaffolding work here can rise tens of meters high, making a detailed hull inspection challenging.

As vessels age, the scope and requirements of hull surveys increase. Vessels undergoing their third or fourth Special Periodic Survey (15 to 20 years old) can incur costs exceeding $1 million just to erect the scaffolding necessary for a hull inspection, which accounts for a significant portion of the overall project cost to achieve Class renewal.

Setting up large scaffolds carries additional safety risks to personnel and operational risks to the vessel. A large workforce is exposed to working at height in confined spaces. Moreover, foreign objects such as scaffold tubes, clips, or tools accidentally left in the tanks can be sucked into cargo pumps, causing damage and leading to unplanned outages when the vessel returns to service. Conversely, rafting presents substantial safety and environmental challenges, including the disposal of vast volumes of oil-contaminated water.

Finding an Alternative Inspection Workflow for Cargo Hull Inspections

An oil tanker fleet operator based in the US needed to conduct a No. 4 Special (20-year-old) periodic survey on one of its tankers. The 250-meter vessel, classed by The American Bureau of Shipping (ABS), was being dry-docked in Southeast Asia to carry out its Class renewal along with some other periodic maintenance work.

The tanker operator, a robotics innovation leader in the marine industry, had been utilizing C-Bird's hull inspection services and had seen the Class-approved capabilities of the Elios 2 for close-up surveys on its fleet for several years. This collaboration had already significantly reduced the need for scaffolding during Class renewal surveys.

The goal was to conduct a hull survey for this ship using the Elios 3, minimizing or eliminating personnel entry into the hull while still gathering all necessary data. Initially, there had been a plan to use a hull inspection ROV to complete the hull survey. However, C-Bird’s experience with the Elios drones made clear that drones were the better choice in this case.

Inspecting a Ship's Hull With the Elios 3 Drone

Although C-Bird pilot Malcolm Connolly had previously used an Elios 2 for similar projects, he opted for the new Elios 3 for this particular ship. He wanted to utilize the LiDAR live map on the Elios 3 to navigate in environments where he couldn’t see the drone, helping guide it. Malcolm was also testing the new UT payload for the Elios 3 to gather ultrasonic thickness measurements.

Malcolm of C-Bird guides the drone around the empty space during the hull inspection.

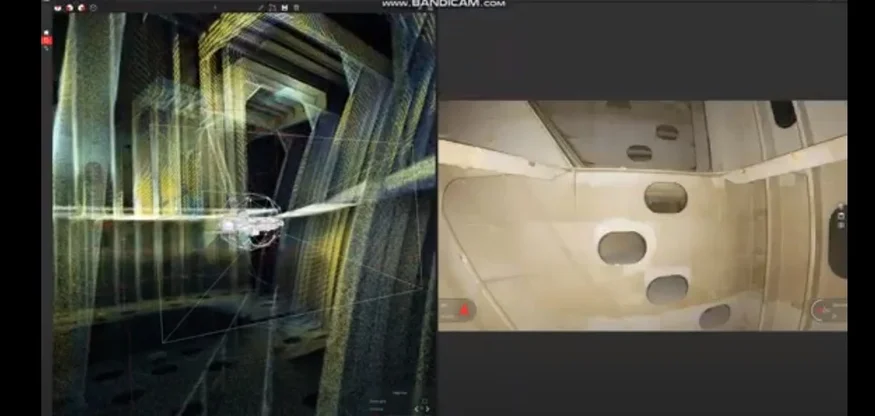

The drone was flown into the cargo tanks as part of the hull inspection without anyone entering the space. Malcolm flew around the entirety of the hull, moving close to gather both 4K video footage and a simultaneous 3D LiDAR scan of structures. The data from the flights was then imported to Inspector 4 for processing.

With processing, the comprehensive results removed any uncertainty about what the drone had surveyed or the location of any anomalies found—the entire space was recreated in 3D as well as clear video footage.

The Elios 3 inspection with the LiDAR data alongside the visual feed.

How the Elios 3 Can Be Used for Hull Inspections in the Maritime Sector?

The Elios 3’s 3D Live Map was successful in helping the C-Bird team ensure full coverage of the correct areas without needing to enter the COTs from the safety of the ship’s deck. In addition to eliminating confined space entry, the mission’s safety and efficiency were further enhanced by negating the need to haul equipment in or out of the tanks, reducing the risk of dropped objects and manual handling requirements, including vessel crew support, as well as reducing the time required to set up for each cargo tank.

Malcolm Connolly, the CEO and founder of C-Bird, said, “The 3D laser scan produced by the Elios 3 allows for accurate localization of data. This takes the entire survey process one step closer to true risk-based asset management and eventually automation. The ability to reliably localize data means you can repeat the survey precisely, measure any state of change between surveys, and then potentially model rates of degradation with machine learning to predict the best maintenance intervention point. This is the direction in which the marine and many other industries want to go!â€

Malcolm highlighted several key benefits of using the Elios 3 for the hull inspection, including:

⦠Full data coverage with the 3D live map ensures that surveyors covered all required areas in the tank despite the large size and uniform features.

⦠Safety improvements through reducing human entry into confined and working at height.

⦠Savings—the drone inspection eliminated the need for scaffolding or prolonged downtime.

⦠Flying in high temperatures—the environment reached 45 degrees Celsius and the Elios 3 was able to handle this environment.

Making Cargo Vessel Hull Inspections Easier With Drone Surveys

Thanks to the Elios 3, C-Bird was able to complete a safer, faster, and more efficient hull inspection. By avoiding the need for scaffolding, over 10,000 hours of working at height were saved.

C-Bird and their client both noticed the simplified logistics of the overall project and highlighted the environmental impact, as this eliminates the need to potentially contaminate water to fill the hull for a rafting-based inspection. They also recognized the drone’s usefulness as an alternative to completing hull inspections with an underwater ROV.

The Elios 3 and its 3D map provided inspectors with enough data for the class renewal through accurate data localization that helped them identify points of interest. This contributed to the success of the project as the ship was successfully reclassified. The overall case study presented by C-Bird demonstrates how the continuing advancement of drone technology is increasing the capabilities of drones in a way that meets the needs of the marine and maritime industry.

Â

Essential Oil Room Diffuser,Non Electric Oil Diffuser,Scented Oil Diffuser Electric,Decorative Essential Oil Diffuser

Guangzhou Chiyang Scent Technology Co., Ltd. , https://www.diffuserscent.com