# Elios 3 Used to 3D Map an Irradiated Storage Vault at DOE Site

## Benefits In A Nutshell

| Best Tool for the Job | Detailed 3D Mapping | Speed |

|-----------------------|--------------------|-------|

| **Best Tool for the Job**

After extensive research, the Idaho Environmental Coalition (IEC), working under contract with the U.S. Department of Energy (DOE), determined that the Elios 3 was the optimal choice for mapping the interior of an underground nuclear waste storage vault constructed in the 1960s. | **Detailed 3D Mapping**

The Elios 3 generated a high-quality 3D map of the vault, offering the precise level of detail required for planning the extraction of nuclear waste. | **Speed**

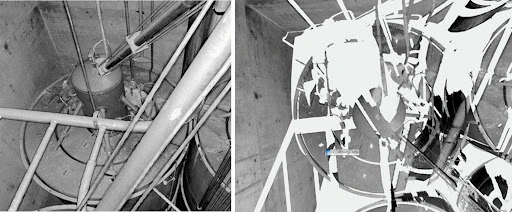

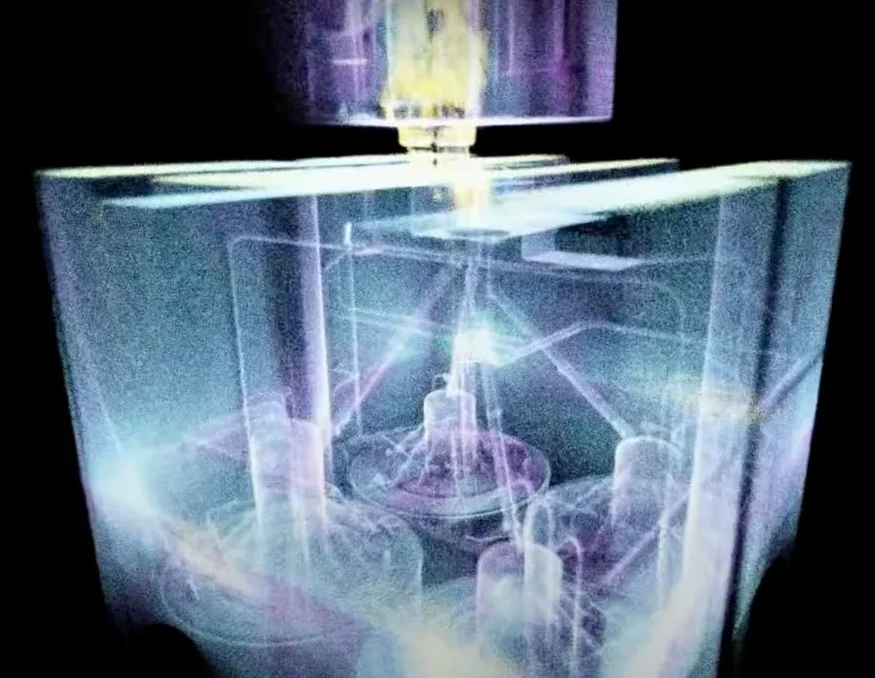

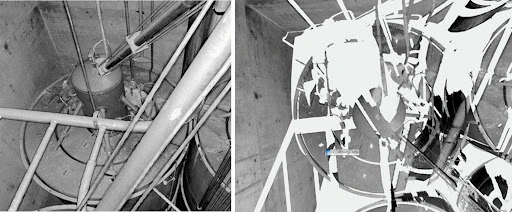

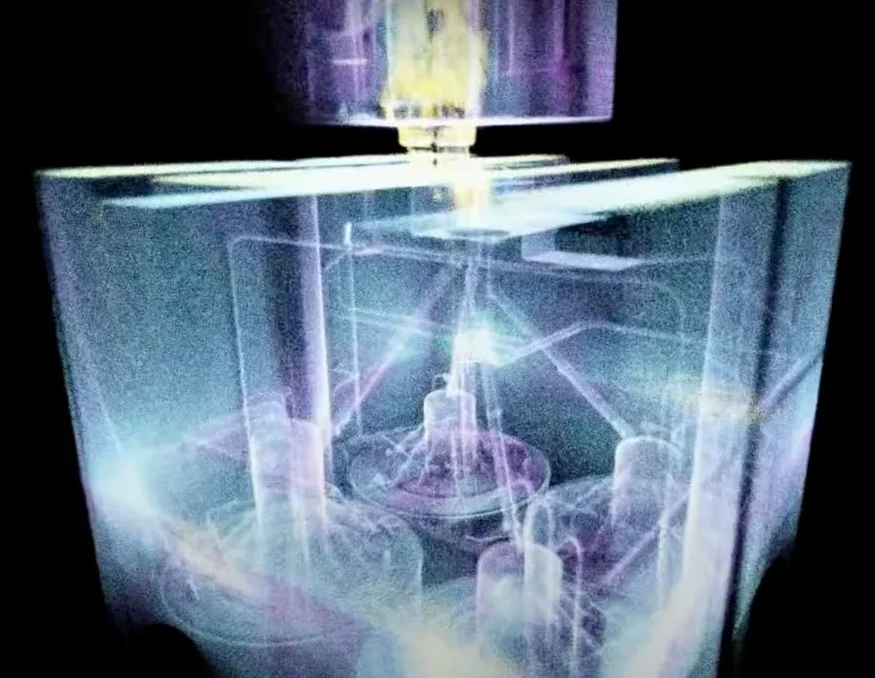

Within just seven minutes of flight time, the IEC was able to gather all the LiDAR data necessary for creating a 3D map of the vault’s interior, marking the culmination of over a year of research and preparation. | ## Introduction In the 1950s, the Department of Energy contracted with the state of Idaho to store 4,400 cubic meters (14,436 cubic feet) of nuclear waste at a secure facility known as the Idaho Nuclear Technology and Engineering Center. This waste, called calcine, is a highly radioactive, granular solid derived from spent nuclear fuel. Stored in six underground vaults, each vault contains bins designed specifically to house the calcine. In 2015, when the DOE’s contract with Idaho came up for renewal, the state decided to remove the waste. This decision necessitated finding both a new storage location and a safe method for its extraction. ## Customer Needs The Idaho Environmental Coalition (IEC) is responsible for planning the removal and transportation of the calcine at the Idaho Nuclear Technology and Engineering Center. One of the first significant milestones in their planning involved developing a method for removing the waste. Their chosen approach includes drilling holes into the top of the storage vault, robotically welding pipes to the tops of each bin, and using a plasma cutter to cut into each bin. These pipes will pneumatically extract the calcine, providing a safe, remote means of removal that greatly minimizes radiation exposure for workers. However, the blueprints for the vaults lack the necessary detail to precisely locate the holes and extraction pipes, making it impossible to plan where to drill without a comprehensive 3D map of the vault’s interior. To address this, the IEC attempted to create a 3D map using a handheld LiDAR sensor mounted on a lowering tripod. Unfortunately, the resulting map had significant gaps due to the sensor being limited to one position.  *Incomplete 3D maps made with the handheld LiDAR data* ## Solution Seeking a solution for creating a complete 3D map of the vault’s interior, the IEC meticulously evaluated five potential approaches, including the use of an articulating arm, a helium-filled blimp, drilling holes into the vault, and one of Flyability’s indoor drones. Each approach was assessed against six key criteria: available project data, technical risk, program complexity, vendor input, project schedule, and budget constraints. Following this exhaustive review, the IEC determined that Flyability’s Elios 2 was the ideal tool for collecting the data needed to map the vault. Initially, the plan was to use visual data from the Elios 2 for photogrammetry-based 3D modeling. However, upon learning about the impending release of the Elios 3, which features a LiDAR sensor, the IEC opted to use the Elios 3 and LiDAR data instead. To prepare, the IEC constructed a full-scale replica of the vault to test the pneumatic retrieval equipment. The replica also proved valuable for training the IEC’s drone pilots, who practiced for the LiDAR data-collection mission. Alongside training, the IEC collaborated with other stakeholders to meticulously plan every detail of the mission. Watch this video to see highlights from the training: ## Results After over a year of research, planning, and preparation, the day of the data collection mission finally arrived. Conditions were challenging—windy and bitterly cold outside—but the interior of the vault was expected to be warmer, creating a temperature fluctuation from -11°C (12°F) to well over 38°C (100°F). These swings could affect the drone’s battery life and performance, causing concern among the team as they prepared for the flight. Over 50 people supported the mission that day. A large tent was erected over the vault’s entrance to ensure the drone remained indoors, adhering to FAA regulations and DOE requirements. A crane was used to remove the heavy concrete cover and open the hatch leading into the vault. Finally, the vault was ready for the flight. The pilot, aware that losing the drone could result in its permanent loss, approached the task with caution. Despite these concerns, the flight was successful. The IEC team gathered all the LiDAR data needed to map the vault’s interior during a single seven-minute flight. Given the extensive preparations, a second flight was conducted to collect additional data, which was equally successful.  *A screenshot of the 3D model made with the LiDAR data collected in the vault* With the vault already open, the team decided to conduct a third flight to gather even more data. After each mission, the LiDAR data was immediately processed using Flyability’s Inspector 4.0 software and GeoSLAM’s GeoSLAM Connect. The resulting 3D models were detailed and accurate enough to meet the IEC’s needs, enabling them to move forward with planning the extraction of the nuclear waste. In just two seven-minute flights, the IEC team achieved everything they needed after over a year of preparation. Here are the key benefits the IEC team realized by using the Elios 3: - **Best Tool for the Job**: Extensive research confirmed that the Elios 3 was the most suitable tool for 3D mapping the vault’s interior. - **Detailed 3D Mapping**: The Elios 3 produced a high-quality 3D map, meeting the precision required for waste extraction planning. - **Speed**: The IEC collected all necessary LiDAR data in just seven minutes, marking the culmination of over a year of preparation. - **Access**: The Elios 3 easily fit through the hatch and accessed the vault, enabling critical remote data collection. - **Ease of Use**: Despite challenging conditions, the Elios 3 performed flawlessly, collecting all required data in two short flights.  *An image taken inside the vault alongside the Elios 3's 3D Live Map* During a third experimental flight, the IEC attached one of its dosimeters to the drone, making it significantly heavier. For reasons not fully understood, the drone was unable to generate enough lift upon entering the vault and slowly descended onto a storage bin, becoming snagged on a piece of angle iron. All efforts to recover the drone failed. Before the battery died, the drone transmitted a maximum radiation reading of 7 Gy/h (700 rad/h) at the top of the bin. Experts analyzed the situation comprehensively and concluded that leaving the drone on the bin posed no risks to human safety or the bin’s integrity. ## Conclusion With the successful mapping of the storage vault, the IEC can now proceed with planning the removal of the calcine using the pneumatic pipe method described earlier. Ultimately, all six vaults must be emptied of their nuclear waste, an endeavor that will demand significant planning and several more months of preparation. This work is projected to begin sometime in mid-2023. Given the success of the Elios 3 in mapping the vault, the IEC and DOE plan to utilize it again for other remote 3D mapping needs in confined spaces.

After extensive research, the Idaho Environmental Coalition (IEC), working under contract with the U.S. Department of Energy (DOE), determined that the Elios 3 was the optimal choice for mapping the interior of an underground nuclear waste storage vault constructed in the 1960s. | **Detailed 3D Mapping**

The Elios 3 generated a high-quality 3D map of the vault, offering the precise level of detail required for planning the extraction of nuclear waste. | **Speed**

Within just seven minutes of flight time, the IEC was able to gather all the LiDAR data necessary for creating a 3D map of the vault’s interior, marking the culmination of over a year of research and preparation. | ## Introduction In the 1950s, the Department of Energy contracted with the state of Idaho to store 4,400 cubic meters (14,436 cubic feet) of nuclear waste at a secure facility known as the Idaho Nuclear Technology and Engineering Center. This waste, called calcine, is a highly radioactive, granular solid derived from spent nuclear fuel. Stored in six underground vaults, each vault contains bins designed specifically to house the calcine. In 2015, when the DOE’s contract with Idaho came up for renewal, the state decided to remove the waste. This decision necessitated finding both a new storage location and a safe method for its extraction. ## Customer Needs The Idaho Environmental Coalition (IEC) is responsible for planning the removal and transportation of the calcine at the Idaho Nuclear Technology and Engineering Center. One of the first significant milestones in their planning involved developing a method for removing the waste. Their chosen approach includes drilling holes into the top of the storage vault, robotically welding pipes to the tops of each bin, and using a plasma cutter to cut into each bin. These pipes will pneumatically extract the calcine, providing a safe, remote means of removal that greatly minimizes radiation exposure for workers. However, the blueprints for the vaults lack the necessary detail to precisely locate the holes and extraction pipes, making it impossible to plan where to drill without a comprehensive 3D map of the vault’s interior. To address this, the IEC attempted to create a 3D map using a handheld LiDAR sensor mounted on a lowering tripod. Unfortunately, the resulting map had significant gaps due to the sensor being limited to one position.  *Incomplete 3D maps made with the handheld LiDAR data* ## Solution Seeking a solution for creating a complete 3D map of the vault’s interior, the IEC meticulously evaluated five potential approaches, including the use of an articulating arm, a helium-filled blimp, drilling holes into the vault, and one of Flyability’s indoor drones. Each approach was assessed against six key criteria: available project data, technical risk, program complexity, vendor input, project schedule, and budget constraints. Following this exhaustive review, the IEC determined that Flyability’s Elios 2 was the ideal tool for collecting the data needed to map the vault. Initially, the plan was to use visual data from the Elios 2 for photogrammetry-based 3D modeling. However, upon learning about the impending release of the Elios 3, which features a LiDAR sensor, the IEC opted to use the Elios 3 and LiDAR data instead. To prepare, the IEC constructed a full-scale replica of the vault to test the pneumatic retrieval equipment. The replica also proved valuable for training the IEC’s drone pilots, who practiced for the LiDAR data-collection mission. Alongside training, the IEC collaborated with other stakeholders to meticulously plan every detail of the mission. Watch this video to see highlights from the training: ## Results After over a year of research, planning, and preparation, the day of the data collection mission finally arrived. Conditions were challenging—windy and bitterly cold outside—but the interior of the vault was expected to be warmer, creating a temperature fluctuation from -11°C (12°F) to well over 38°C (100°F). These swings could affect the drone’s battery life and performance, causing concern among the team as they prepared for the flight. Over 50 people supported the mission that day. A large tent was erected over the vault’s entrance to ensure the drone remained indoors, adhering to FAA regulations and DOE requirements. A crane was used to remove the heavy concrete cover and open the hatch leading into the vault. Finally, the vault was ready for the flight. The pilot, aware that losing the drone could result in its permanent loss, approached the task with caution. Despite these concerns, the flight was successful. The IEC team gathered all the LiDAR data needed to map the vault’s interior during a single seven-minute flight. Given the extensive preparations, a second flight was conducted to collect additional data, which was equally successful.  *A screenshot of the 3D model made with the LiDAR data collected in the vault* With the vault already open, the team decided to conduct a third flight to gather even more data. After each mission, the LiDAR data was immediately processed using Flyability’s Inspector 4.0 software and GeoSLAM’s GeoSLAM Connect. The resulting 3D models were detailed and accurate enough to meet the IEC’s needs, enabling them to move forward with planning the extraction of the nuclear waste. In just two seven-minute flights, the IEC team achieved everything they needed after over a year of preparation. Here are the key benefits the IEC team realized by using the Elios 3: - **Best Tool for the Job**: Extensive research confirmed that the Elios 3 was the most suitable tool for 3D mapping the vault’s interior. - **Detailed 3D Mapping**: The Elios 3 produced a high-quality 3D map, meeting the precision required for waste extraction planning. - **Speed**: The IEC collected all necessary LiDAR data in just seven minutes, marking the culmination of over a year of preparation. - **Access**: The Elios 3 easily fit through the hatch and accessed the vault, enabling critical remote data collection. - **Ease of Use**: Despite challenging conditions, the Elios 3 performed flawlessly, collecting all required data in two short flights.  *An image taken inside the vault alongside the Elios 3's 3D Live Map* During a third experimental flight, the IEC attached one of its dosimeters to the drone, making it significantly heavier. For reasons not fully understood, the drone was unable to generate enough lift upon entering the vault and slowly descended onto a storage bin, becoming snagged on a piece of angle iron. All efforts to recover the drone failed. Before the battery died, the drone transmitted a maximum radiation reading of 7 Gy/h (700 rad/h) at the top of the bin. Experts analyzed the situation comprehensively and concluded that leaving the drone on the bin posed no risks to human safety or the bin’s integrity. ## Conclusion With the successful mapping of the storage vault, the IEC can now proceed with planning the removal of the calcine using the pneumatic pipe method described earlier. Ultimately, all six vaults must be emptied of their nuclear waste, an endeavor that will demand significant planning and several more months of preparation. This work is projected to begin sometime in mid-2023. Given the success of the Elios 3 in mapping the vault, the IEC and DOE plan to utilize it again for other remote 3D mapping needs in confined spaces.

Catalyst Tube,Reformer Tube,Steam Reforming Tube,Centrifugal Casting Reformer Tube

Tuopu Industry(Jiangsu) Co., Ltd. , https://www.tuopu-industry.com