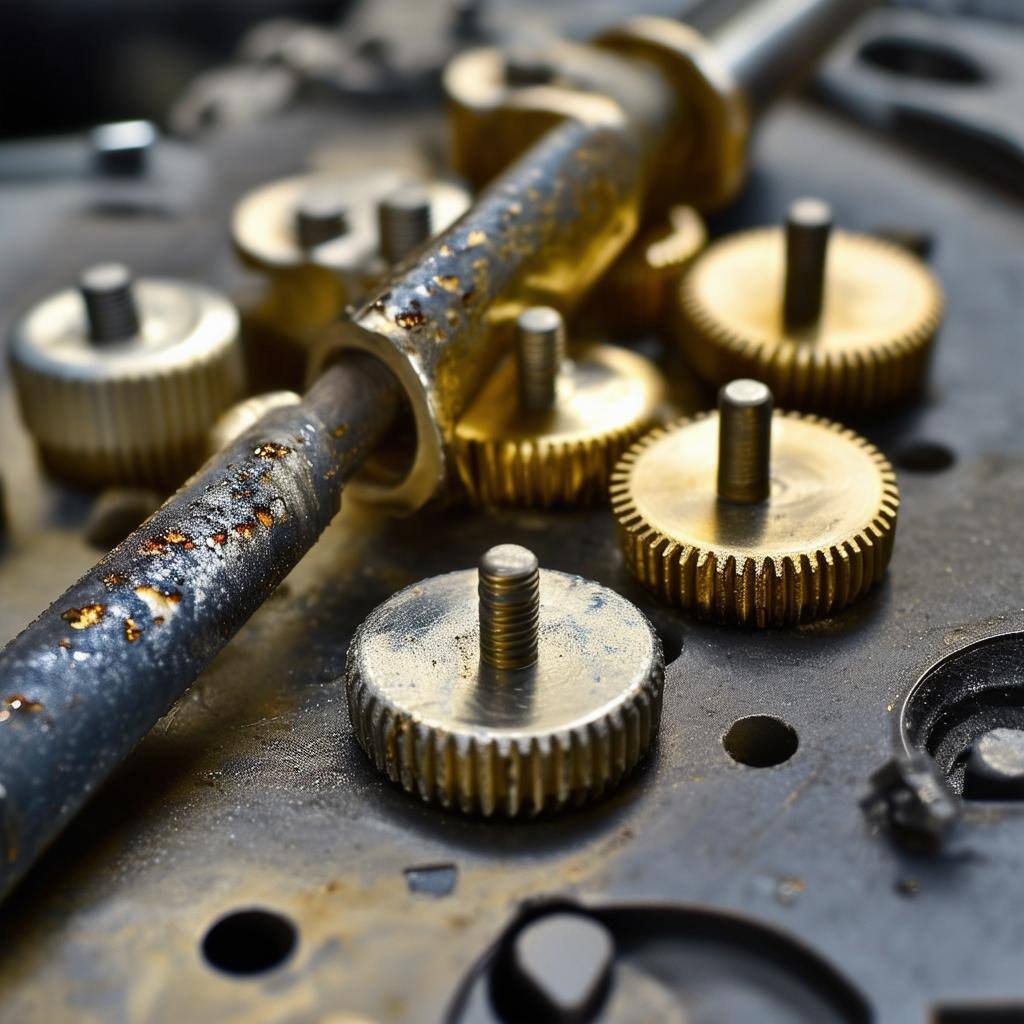

In the vast world of manufacturing, standard pins play a significant role due to their widespread use and availability. Thanks to numerous manufacturers and a consistent supply chain, finding standard pins at competitive prices is relatively straightforward. However, there are specific situations where standard pins simply don't suffice—especially in harsh environments where they might need to function as connectors or connections.

Take industries like heavy machinery, industrial sectors, and military/aerospace, for instance. These fields frequently deal with challenging environmental conditions, including extreme temperatures, physical stress, and exposure to corrosive substances like acids or humidity. Imagine a scenario where a standard pin fits perfectly into your design but is vulnerable to rusting when exposed to outdoor elements. In such cases, opting for a custom-plated pin from a reputable manufacturer like Bead Electronics can make all the difference. Their custom-plated pins offer superior durability and reliability, ensuring optimal performance even under adverse conditions.

When creating products like automobiles, aircraft, or medical devices, reliability becomes paramount. The safety and functionality of these items often depend on maintaining stable electrical connections, regardless of the surrounding conditions. This is why using contact pins designed to endure environmental and mechanical stresses is essential. Bead Electronics focuses on crafting custom contact pins using robust materials and advanced coatings, ensuring their products can handle any challenge thrown at them.

There are countless ways to customize your pins, allowing you to tailor them precisely to your requirements. Whether it's adjusting size, selecting the base metal, or choosing the right plating material, every detail can be fine-tuned for maximum effectiveness. For instance, if corrosion resistance is critical for your application, consider noble metal plating or surface treatments. When facing physical stress, a Phos Bronze pin proves far more resilient compared to a Copper pin. Similarly, replacing a Brass alignment pin with a Steel one helps eliminate cross shear issues. If shock and vibration resistance are concerns, Bead Electronics provides reinforced mechanical designs to address those needs effectively.

Moreover, Bead Electronics offers an array of unique pin geometries compatible with specialized connector housings, providing versatility unmatched by standard pins. Some metals naturally conduct electricity better than others, so exploring custom plating options can help identify the ideal metal for your application.

If you're unsure how to proceed with customization, delve into our range of hollow and solid wire variables to discover all possible customization opportunities. Need further assistance? Feel free to reach out—we’re here to guide you through the process.

At Bead Electronics, we pride ourselves on delivering end-to-end solutions for custom wire and hollow pins. With rapid turnaround times as short as two weeks, we can design and produce tailored pins that meet your specifications without compromising affordability. Reach out to us today to kickstart your project!

Wuxi Yacai Precision Machinery Co., Ltd , https://www.yacaijm.com