The Importance of Proper Robot Operator Training

As robotic automation becomes more prevalent in manufacturing and industrial settings, the need for well-trained operators has never been greater. Proper training ensures that operators can efficiently manage robotic systems, maintain productivity, and adapt to new technologies as they emerge. A trained operator is not just a user—they are an essential part of the system’s success.

There are numerous robot training programs available, many offered by integrators or specialized educational institutions. Choosing the right program can make a significant difference in how effectively your team can operate and maintain robotic equipment. The investment in training pays off in the long run through increased efficiency, fewer errors, and improved safety standards.

The Benefits of Robot Operator Training

One of the most immediate benefits of proper robot operator training is increased productivity. When operators are well-versed in the systems they work with, they can reduce setup time, minimize errors, and optimize performance. This is especially important when new robots are introduced into the workflow, as training helps shorten the learning curve and prevent costly downtime.

Safety is another critical aspect of robot training. Operators who understand the risks associated with robotic systems are better equipped to follow safety protocols, reducing the likelihood of accidents. This not only protects workers but also minimizes disruptions caused by incidents that could halt production.

Additionally, trained operators can help maximize the return on investment (ROI) of robotic systems. With advanced knowledge, they can troubleshoot issues quickly, perform routine maintenance, and ensure that the robotic cell runs at peak efficiency. This leads to longer equipment life, lower repair costs, and consistent output quality.

What to Look for in a Robot Training Program

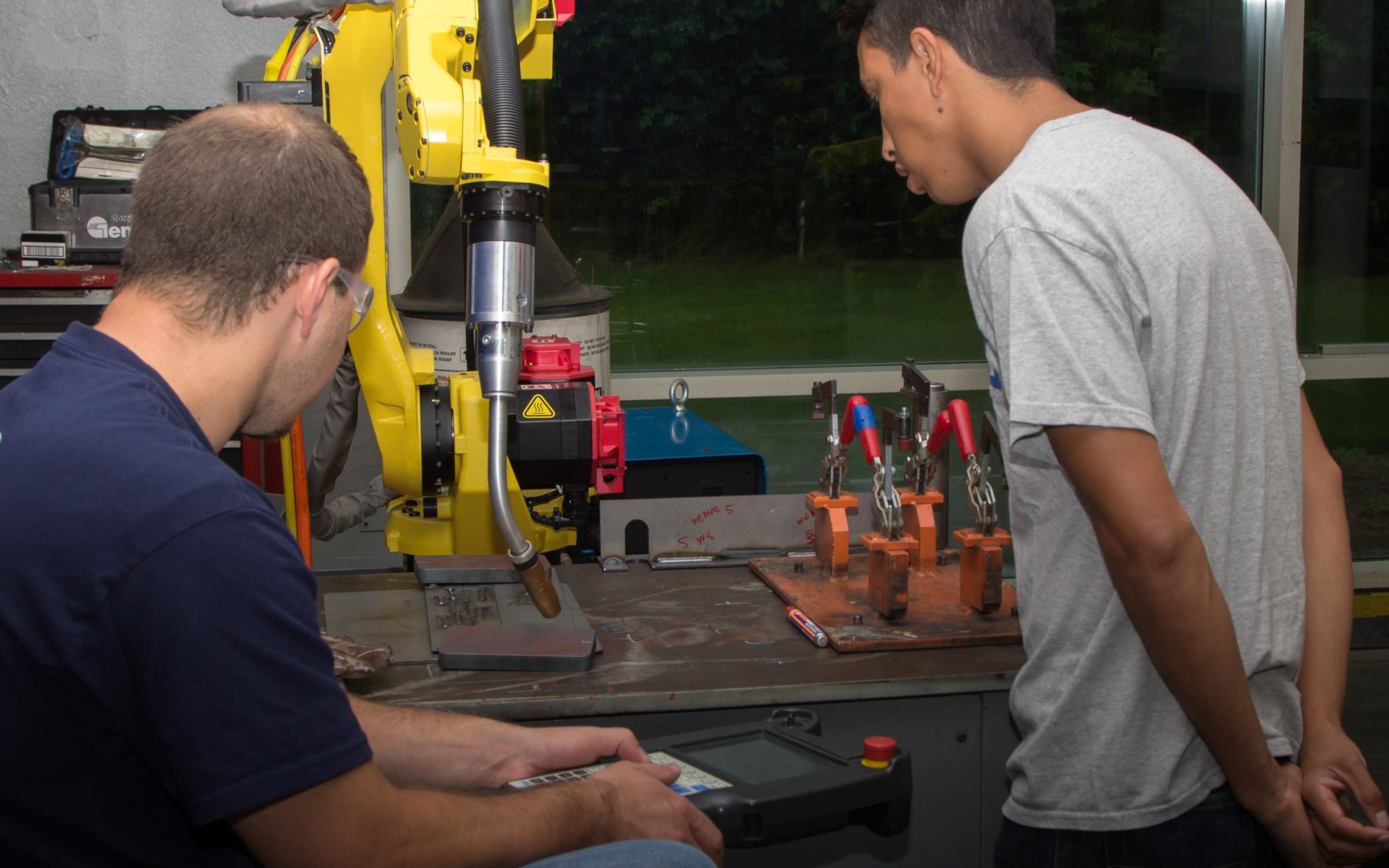

Not all training programs are created equal. When selecting a program, it's important to look for one that offers hands-on experience. Small class sizes allow for personalized instruction, and direct interaction with robotic systems helps reinforce learning. Ideally, a program should balance theory with practical application—around 20% lecture and 80% hands-on work is often considered ideal.

Another key factor is the expertise of the instructors. A good training program should be led by experienced professionals who have worked with various types of robots and programming languages. They should be able to tailor the curriculum to the specific needs of the participants, ensuring that the training is relevant and applicable to real-world scenarios.

Robot technology is constantly evolving, so ongoing education is crucial. A strong training program not only teaches current skills but also equips operators with the ability to learn and adapt as new systems are introduced. This ensures that your workforce remains competitive and capable of supporting future advancements.

If you're looking for high-quality, hands-on robot training, consider exploring programs like those offered by Genesis Systems Group. Their courses are designed to provide real-world experience and equip operators with the knowledge they need to succeed in today’s automated environments.

Posted in UncategorizedDouble Sided Printed Lined Paper

Double Sided Printed Lined Paper,Double Sided Tobacco Lining Paper,Tobacco Lining Paper,Moisture Proof Tobacco Lining Paper

Jilin Changbaishan Packaging Materials Co., LTD , https://www.cbsbz.com